Hyperbaric Safety is a TEAM effort - Every role, every checklist, and every voice matters in protecting patients and staff.

Rx Pad

I'd like to share an article that applies to all professionals in the field of hyperbaric medicine, including new, aspiring chamber operators. This article is designed to provide a helpful overview and to alleviate fears or apprehensions that may arise during your new journey into the amazing field of hyperbaric oxygen treatments.

Copyright

© Republished with permission from the Hyperbaric Certification Commission gethcc.com

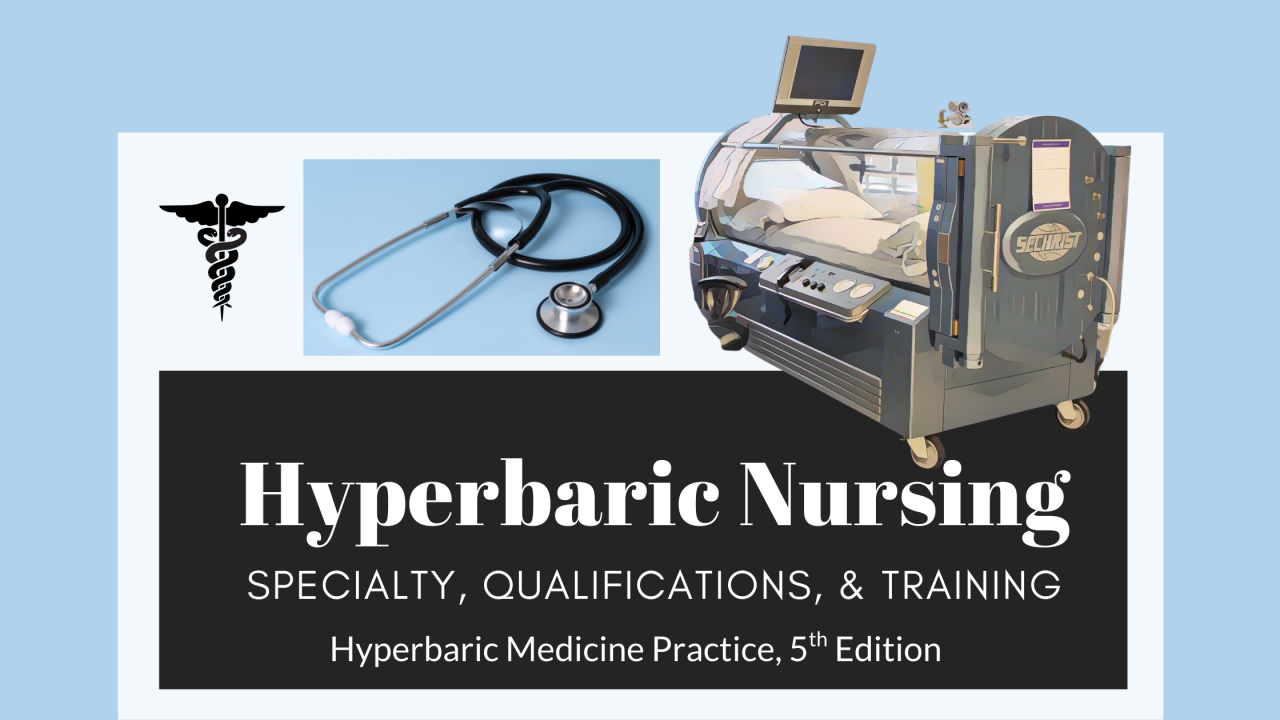

Choosing Hyperbaric Nursing as a speciality.

The specialty of hyperbaric nursing was formally recognized with the founding and incorporation of the Baromedical Nurses Association (BNA) in 1985. The BNA was established with 35 founding RN members at the joint meeting of the UMS Annual Scientific Meeting and the Long Beach Clinical Hyperbaric Conference. The BNA, which is international in scope, maintains a membership of 250 registered nurses from approximately five countries. Functions of the BNA include promoting professional activities that enhance the effectiveness of hyper-baric nursing in the health-care system and promoting educational opportunities and networking for nurses practicing in the specialty. Educational activities of the BNA can now be accessed online and focus on chamber and patient safety, patient compliance, evidence-based best practices, and quality improvement programs.The BNA develops and maintains standards-of-care guidelines in hyperbaric nurs-ing and supports nursing research efforts.(1,2)

Aerospace Medical Association &

Undersea and Hyperbaric Medical Society:

The concepts of quality improvement (QI) and performance improvement (PI) in healthcare are not new and have been around in some form for many years. Implementing best practices and establishing quality and safety standards ensures that a hyperbaric department attains a high level of safe patient care.

Five years ago Wound Care Education Partners wrote a blog "How to Become Certified in Hyperbaric Medicine". In those years since the original post the field Hyperbaric Medicine has grown significantly. According to hyperbaric oxygen therapy market insights the CAGR (Compound Annual Growth Rate) for hperbaric medicine s expected to increase by 5.8% over the next four years. (TechNavo; Jan 2025, "Hyperbaric Oxygen Therapy Market Size 2025-2029" )

This 5th Edition of Hyperbaric Medicine Practice, captained by Dr. Harry T. Whelan, is the most robust and monumental information source for undersea and hyperbaric medicine to date. Split into two volumes due to its size and detail, this 5th edition boasts six new chapters. With the help of 70 contributors from all over the world, Hyperbaric Medicine Practice has become the go-to authority for both studying and practicing hyperbaric medicine professionals.

Analysis of hazards and risk assessment allows us to understand the true nature of the potential incident we are attempting to manage. This is an important first step in designing a contingency plan. There are several other important considerations that affect the design of the plan. Realizing the potential damage or injury helps us to identify appropriate staff responses. These responses should minimize the impact of the incident. It is important to consider what personnel are available to help (e.g., additional staff members, code team, and emergency responders) and how these individuals are capable of participating in the plan. Designing contingency plans with available personnel in mind drives minimum facility staffing decisions. It is also important to consider what equipment is available (e.g., personal protection, patient transportation, fire-fighting, and crash cart). All the considerations discussed above are likely to vary among different hyperbaric facilities.

In this third and final installment of How Accidents Happen we continue looking at personnel & management as contributing factors in hyperbaric facility accidents.

When one commences a task to reconstruct how an accident happened, personnel and management factors are often “at the head of the class.” Some of the more commonly occurring factors are discussed in this section. It should be noted, however, that this list is not all-inclusive. The factors that can contribute to accidents are many and varied. As technology and operations become ever more complex, our ability to create new ways to “do ourselves in” are amazing.

For some accidents there is a clear “smoking gun.” However, most accidents are caused by a combination of factors, each of which contributes in some manner. Often these factors accumulate over some period of time preceding the accident. This chapter addresses the factors that foster conditions under which accidents are more likely to happen and discusses some of the steps to be taken to avoid them. Also included is a case history illustrating several of the factors.

Analysis of hyperbaric facility risks is a difficult process. It begins with identifying the hazards in a hyperbaric facility. These hazards could be from a variety of sources: equipment related (e.g. loss of power, loss of gas supply, control system malfunction); operational (e.g. untrained or unprepared staff); medical (e.g. pressure injuries, medical complica- tions); and environmental (e.g. contaminants, external disaster). The actual risks associated with a hazard depend on the probability, frequency, and severity of the potential losses.

Hyperbaric emergency procedures usually address a variety of problems ranging from mechanical malfunction to medical complications—important events that do not seem to share a common trait but cover a wide range of situations. Such a variable group of events must be discussed in a broad context. This chapter will discuss emergency pro- cedures within the framework of the entire hyperbaric safety program. In this broader context, events that may or may not be emergencies belong together. That is why this dis- cussion will replace the term “emergency procedure” with the term “contingency plan.”

In general, fire prevention is described in terms of the Fire Triangle model. For a fire to occur, a fuel, an oxidizer, and an ignition source must be present. Fire prevention in a hyperbaric chamber must account for an increase in the oxygen component of the atmosphere in terms of both oxygen fraction and partial pressure. The resultant increase in oxygen renders what might be inactive fuels and ignition sources in a “normal” air environment active, which increases the risk of a fire.

Safety in a hyperbaric chamber begins with design and specifications that are incorporated in construction codes such as the ASME Boiler and Pressure Vessel Code. ASME and related codes establish minimum standards for materials utilized in the construction of a chamber and how those materials are fabricated.2 Subcodes address specific requirements for pressure vessels intended for human occupancy and the viewports utilized in the chamber.3 ASME codes focus on maintenance of the structural integrity of the chamber during routine operations as well as providing safety components such as pressure relief valves to reduce the potential for catastrophic failure of the chamber in the event of overpressure resulting from fire or other mishap. A chamber will undergo inspection, testing, and be stamped to indicate that it has been manufactured in compliance with the applicable pressure vessel code. In many locales, only stamped pressure vessels are allowed to be utilized.

For some accidents there is a clear “smoking gun.” However, most accidents are caused by a combination of factors, each of which contributes in some manner. Often these factors accumulate over some period of time preceding the accident. This chapter addresses the factors that foster conditions under which accidents are more likely to happen and discusses some of the steps to be taken to avoid them. Also included is a case history illustrating several of the factors.

There are two distinct aspects to the field of hyperbaric medicine that influence safety:

Copyright

© Republished with permission from the Hyperbaric Certification Commission gethcc.com

We receive a number of phone calls each week from folks inquiring how to become a Certified Hyperbaric Technologist (CHT). The added qualification of CHT is administrated by the National Board of Diving and Hyperbaric Medical Technology (NBDHMT).

Copyright

© Republished with permission from the Hyperbaric Certification Commission gethcc.com

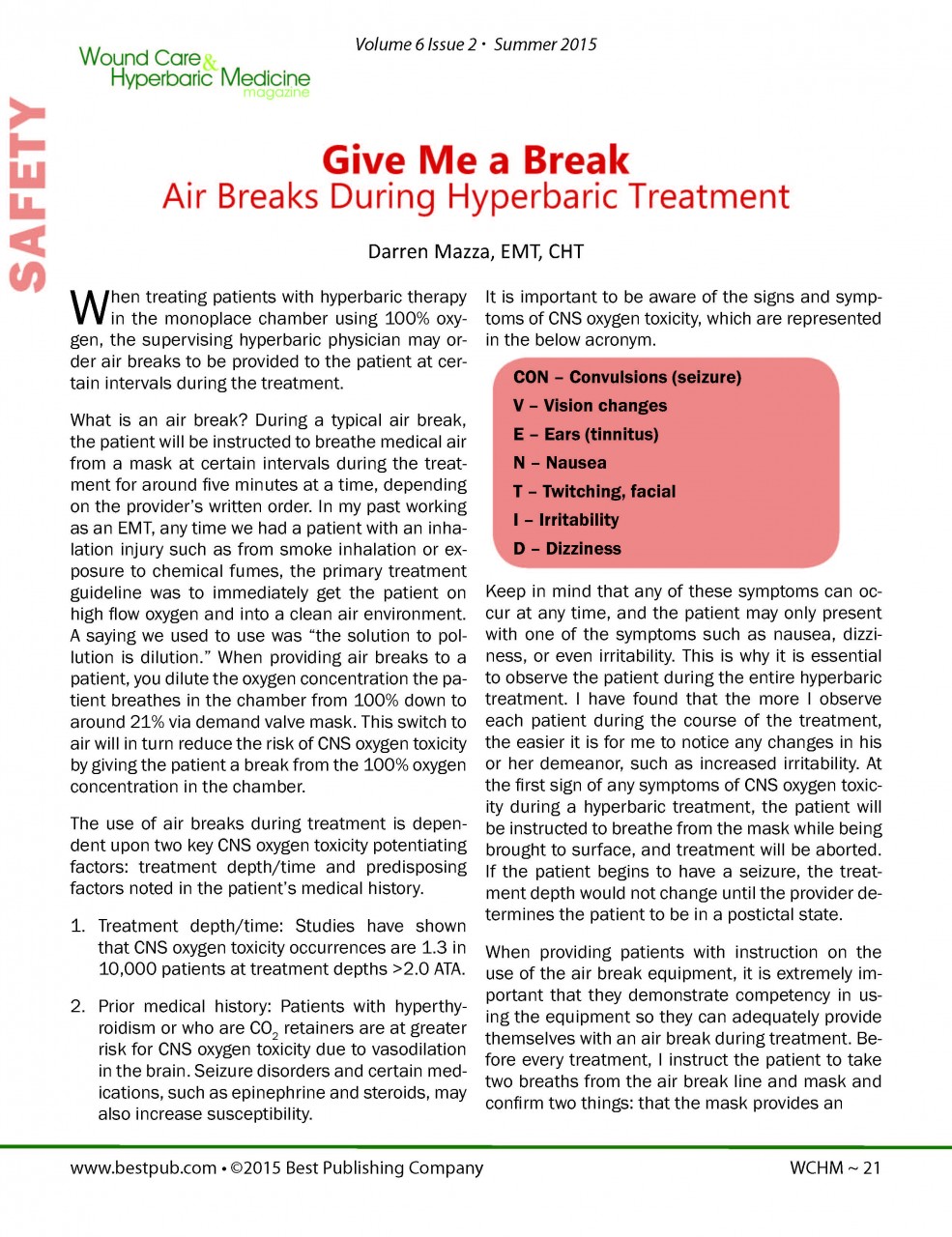

When treating patients with hyperbaric therapy in the monoplace chamber using 100% oxygen, the supervising hyperbaric physician may order air breaks to be provided to the patient at certain intervals during the treatment.

Copyright

© Republished with permission from the Hyperbaric Certification Commission gethcc.com

This article will provide you with some background on liquid oxygen, which is the most common form of bulk storage for this gas. The manufacture, storage, basic design of a liquid oxygen converter, and general safety practices will be covered. Again, keep in mind that working around oxygen has its hazards, but working around a liquid oxygen system can be outright deadly if you have not been properly trained.

Copyright

© Republished with permission from the Hyperbaric Certification Commission gethcc.com

We are often asked the question, "Does participation in a safety director course automatically designate me as a hyperbaric safety director?" There seems to be some midunderstanding around this issue.

Copyright

© Republished with permission from the Hyperbaric Certification Commission gethcc.com

The development of a comprehensive maintenance program for a hyperbaric system and its supporting equipment is essential for a safe and cost-effective operation. The chamber and its operational systems, the chamber room, and the equipment used in and around the chamber should be maintained at the highest operational level. This should also include the cleanliness of all elements of the interior and exterior systems.

Copyright

© Republished with permission from the Hyperbaric Certification Commission gethcc.com

![[Free Webinar] Introduction to the Role of Hyperbaric Safety Director](https://mail.woundeducationpartners.com/images/easyblog_images/176/b2ap3_large_Hyperbaric-Safety-Director-Course_w_20160223-163441_1.jpg)